Content

Demand Media said many companies like cycle stock because it indicates a high demand for products. Businesses don’t have to pay for overhead or maintenance fees associated with long-term storage.

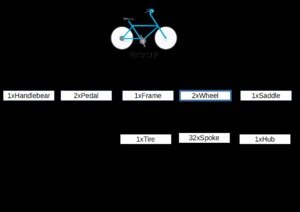

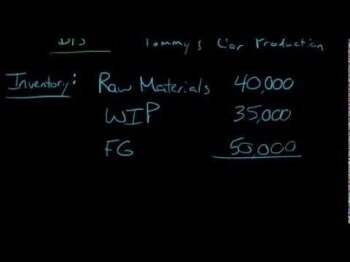

The cost of efficiency must be weighed against the cost of carrying excess inventory so that there is an optimum balance between inventory level and coordination within the system. Any item that has a parent but is not a raw material is considered to be work-in-process. A glance at the rolling cart product structure tree example reveals that work-in-process in this situation consists of tops, leg assemblies, frames, legs, and casters.

From the product structure tree it is apparent that the rolling cart’s raw materials are steel, bars, wheels, ball bearings, axles, and caster frames. Don’t forget to choose the right type of inventory costing method to complement your choice of inventory management system.

One of my first jobs was as a sales assistant in a small clothing store in my hometown. At the age of 16, I was told that I would be required to stay until 10 p.m.

Third-party logistics is about getting your products to customers using a third-party to complete fulfillment. inFlow provides powerful inventory management and product ordering capabilities for SMBs. RFID is a technology that uses radio waves between a tag and a reading device. The reader reads data from the tag, which usually includes an identifying inventory number or product-related information such as stock and batch numbers and production dates. Barcode inventory systems use numbers to identify each product being sold. The store no longer exists, but the memory of terrible inventory management lives on. A good inventory management system is truly the backbone of a successful business.

When the two costs are equal (holding/carrying costs and ordering/setup costs) the total cost is minimized. Cycle inventories, sometimes called lot-size inventories, result from this process. Usually, excess material is ordered and, consequently, held in inventory in an effort to reach this minimization point. Hence, cycle inventory results from ordering in batches or lot sizes rather than ordering material strictly as needed. A finished good is a completed part that is ready for a customer order.

Inventory Articles

A complete data history that integrates market performance, supplier actions, manufacturing processes and supply chain performance helps companies anticipate inventory needs. Mobilizing inventory management for your company’s ERP allows manufacturing teams and warehouse workers to communicate inventory activities in a central source. Mobile barcoding enables real-time material transactions against the ERP, wherever they work. Mobility software can distinguish between unused materials, stored goods and consumption, making it simple to track all material types accurately and efficiently. You might sell some products exactly as you bought them, while modifying others.

Inventory are current assets that are expected to be sold by a business. If your count and your POS system’s inventory record don’t match, you have a discrepancy and your inventory isn’t 100% accurate. If your count has fewer counted items than your POS, you’ve lost items to shrinkage.

There are two other crucial types of inventory, namely packing material inventory and MRO supplies inventory. Keeping track of all that inventory can feel overwhelming, especially if your products are stored all over the place. This is especially true if you are still using outdated systems like spreadsheets.

Dedicate certain areas to specific product types to make it easier for your staff to find additional sizes, replenish shelves and count inventory when the time comes. These various courses can allow you to fully understand the five types of inventory and more. You will become adept in inventory management and will understand its true uses. There are three types of businesses such as trading or merchandising, manufacturing, and service. Here, the first classification of inventory is based on the nature of business – Merchandise and Manufacturing Inventory.

Packing Materials

Business Checking Accounts BlueVine Business Checking The BlueVine Business Checking account is an innovative small business bank account that could be a great choice for today’s small businesses. Appointment Scheduling 10to8 10to8 is a cloud-based appointment scheduling software that simplifies and automates the process of scheduling, managing, and following up with appointments. Stay updated on the latest products and services anytime anywhere. Reproduction of materials found on this site, in any form, without explicit permission is prohibited. Supplies that are consumed in the production of a product or service that aren’t part of the product itself. Partially finished goods waiting for completion such as a stock of bicycles waiting for tires at a bicycle factory.

Work-in-progress materials are items in the process of being manufactured as a part of a final product. This may be prepared wood, molded plastics, or cut steel pieces. Transit inventories result from the need to transport items or material from one location to another, and from the fact that there is some transportation time involved in getting from one location to another. Merchandise shipped by truck or rail can sometimes take days or even weeks to go from a regional warehouse to a retail facility. Of course, this can greatly increase the transit time for these inventories, hence an increase in the size of the inventory in transit.

Other reasons can be availing price discount on bulk purchases, guard against market shortage situation, etc. The manufacturing process is applied to the raw material to produce desired finished goods.

Business Types

Operating supplies include the stationery and office supplies used by a company. management systems are necessary for maintaining a successful cycle of supply and demand.

- The extent of inventory locked-up as work in progress is lower the better.

- Raw materials are inventory items that are used in the manufacturer’s conversion process to produce components, subassemblies, or finished products.

- The management of inventory calls for an optimum level of inventory that can be maintained by creating an inventory purchasing plan as per the strategy adopted by the company.

- There are lots of different schools of thought on the best way you decide when to reorder your products.

In essence, RFID inventory systems take barcode systems one step further. They are capable of reading tags from 40 feet away and don’t require line-of-sight scanning. This makes RFID systems a good choice for businesses that operate warehouses or distribution centers with large amounts of stock and utilize multi-level storage.

ABM Inventory is a SaaS system designed for retail, wholesale sectors. Finished products are the final items after every step is complete. Inventory Management software is used to track, manage and organize inventory levels, orders, sales and invoices.

Every employee who talks with a supplier should record the details of the interaction into the central data system. Inventory has different classifications at different points in the supply chain.

Since everything is recorded by hand, a periodic inventory management system also doesn’t provide up-to-date stock and inventory levels. However, it can be a burdensome system for larger businesses that run with greater amounts of stock because of a higher probability of inaccuracies. Periodic systems notoriously don’t have a great track record of being able to identify mistakes and inventory shrinkage stemming from loss, theft, and damages.

Remember, that’s the inventory that accounts for 80% of your total revenue. Next, compare the results of your inventory count to what your POS system thinks you have. In their backstores, men’s, women’s and children’s footwear each have a dedicated section . purchase order to your supplier, and you know what quantity you need to order to maintain your desired amount of inventory on hand. Secondary packing is something used to pack the goods so that they don’t get damaged during handling, transportation, etc. or to make the goods appear more appealing to the customers.